Blog

How to Fix a Hole in Your Cylinder Block

There is only really one way to fix it a hole in a cylinder block and that is to replace it.

If you have a Perkins 212 , 236 or 248, Noordeman Diesel may have the answer to your problem.

Basic specs on a Perkins 4-212 , 4-236 and 4-248

| Engine type | 212 | 236 | 248 |

| Bore size | 3.8750 | 3.8770 | 3.9750 |

| Stroke | 4.50 | 5.00 | 5.00 |

| Square back Non stress block | Yes | Yes | Yes |

| Flanged back stress block | No | Yes | Yes |

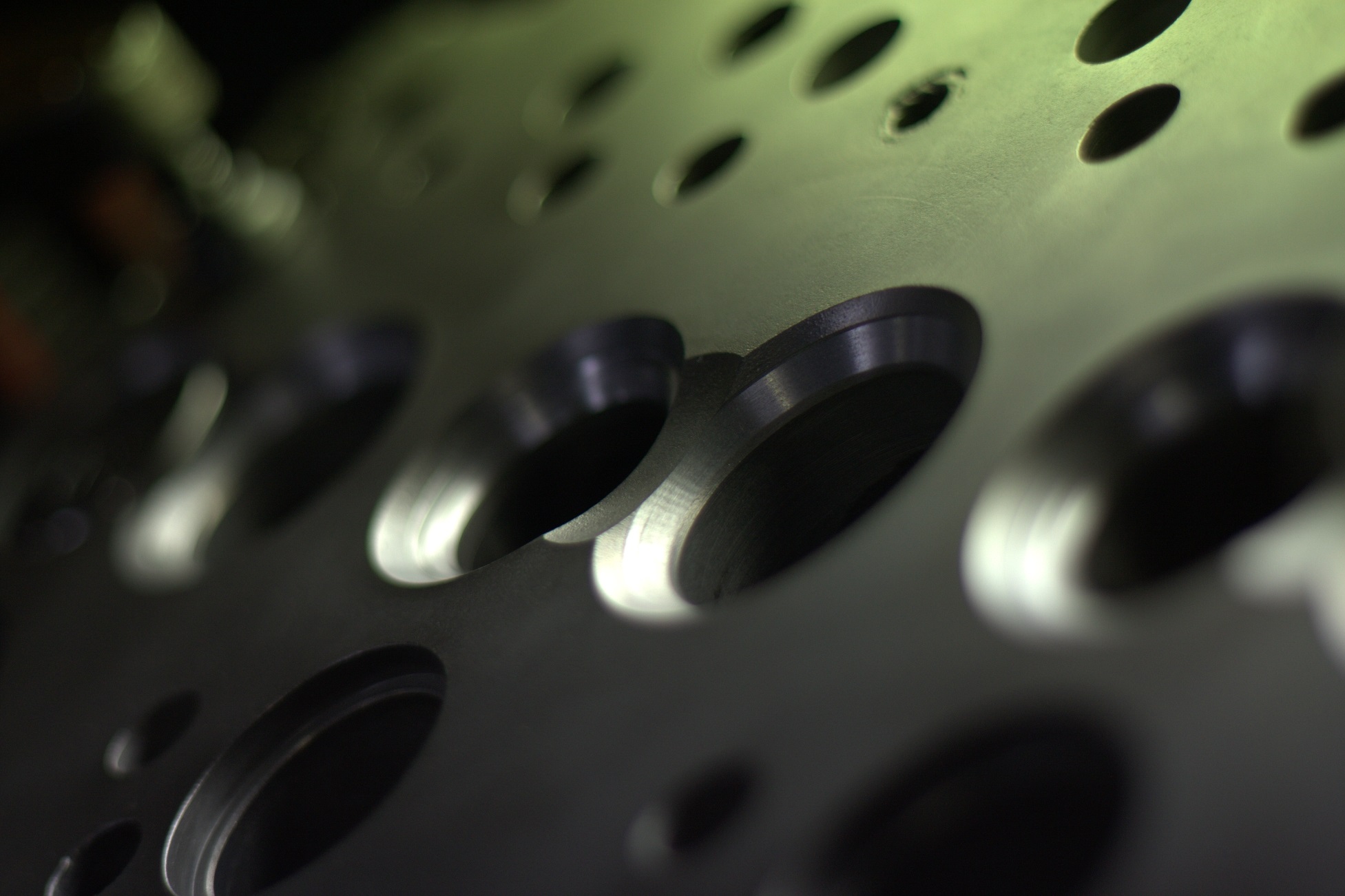

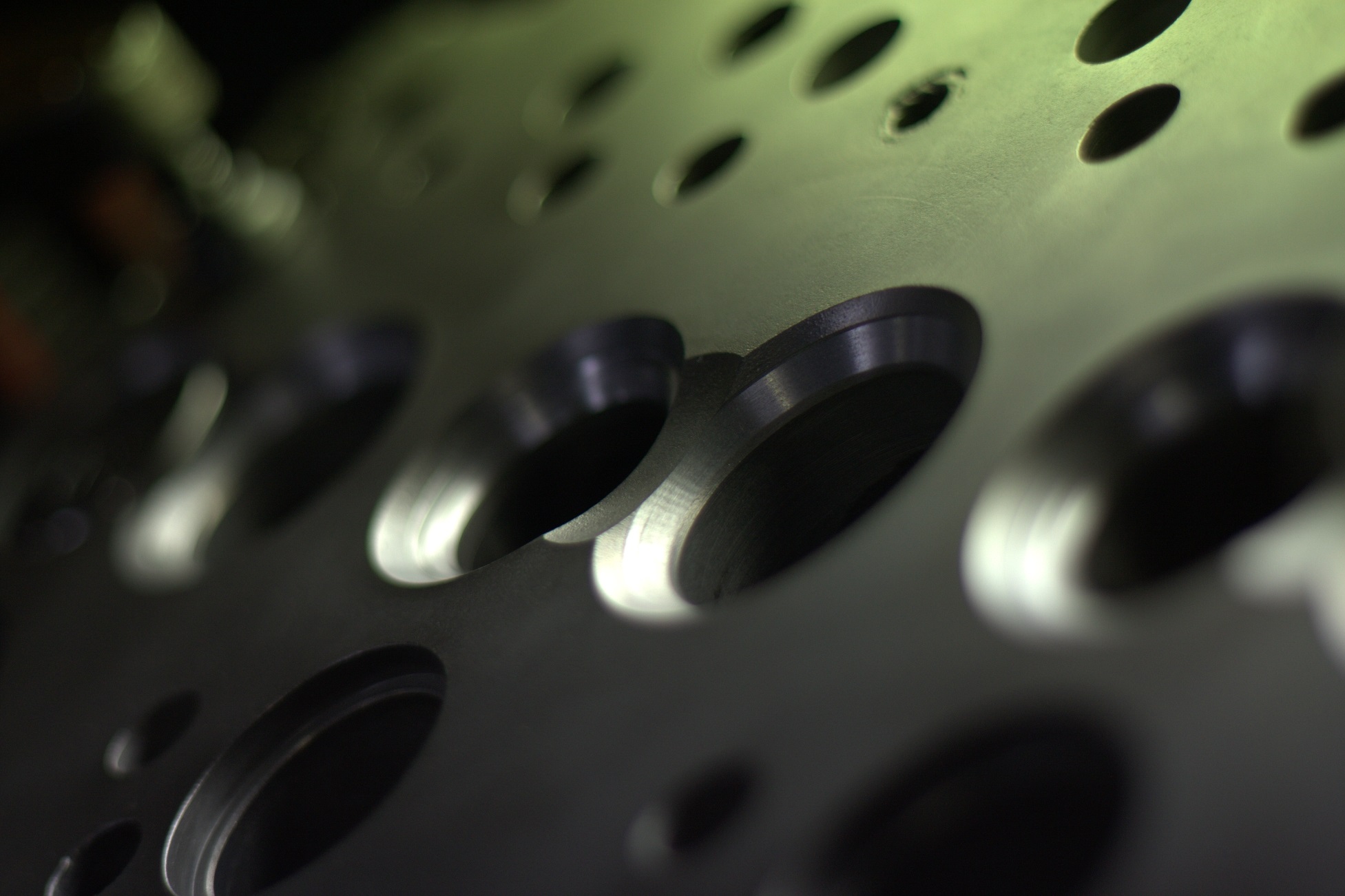

Cylinder blocks

- You can use a 212 cylinder block to make a 236 or a 248 Perkins or vice versa, they all can be modified to replace each other.

- You can convert a 4-236 to be a 248, but you won’t really notice that much difference in extra HP. Fuel system can stay the same.

- There are flange liner blocks and non-flange liners (non flanged liners are known as parallel liners)

- The early type cylinder blocks have flanged and parallel liners fitted . The top of the liner protrudes and this in known as the fire ring.

- Fire rings type liners require top set u5lt1014 click here for the link

- The later type 4-236 blocks have flanged liners. These have no fire ring and the top on the liner is flush with the top of the cylinder block.

- 236 flanged liners are available STD and over size, you can get .010 and .040 over size backs.

- Non-fire ring type blocks require a different top gasket set U5lt1004 click here for the link

- You can convert a chrome liner block to a cast liner block, by changing the counter bore depths.

Crankshafts

- 212 crankshaft has a different stroke to a 236 and 248.

- 236 and 248 crankshafts are the same, there are some variations

- There are balance weight and non-balance weight types.

- Lip seal or rope seal.

- Splined nose or non-splined nose.

- Non spline nose cranks have 3 bolt holes – splined nose has 1 bolt hole.

Conrods

- All the conrods are the same and interchangeable.

- All small end bushes are the same.

- Conrod nuts and bolts are the same.

Cylinder Heads

- 212, 236, 248 all cylinder heads the same and interchangeable

- All valves and springs are interchangeable

More Specifications below

212 Flanged Cast Iron Liners:

Parent Bore Diam: 4.0625-4.0635″

Recess Depth: 0.150 -0.152″

Outside Diameter: 4.0645-4.0655″

Interference Fit: 0.001 -0.003″

Piston Height: 0.015 -0.021″

Finished Bore Diameter: 3.877 -3.878″

236 Flanged cast liners”

Parent Bore: 4.0625-4.0635″

Recess Depth: 0.150 -0.152″

Outside Diameter: 4,0645-4.0655″

Interference Fit: 0.001 -0.003″

Piston Height: (above) 0.003 -0.010″

Finished Bore Diameter: 3.877 -3.878″

236 Parrallel liners”

Parent Bore: 4.0625-4.0635″

Recess Depth: N/A

Outside Diameter: 4,0645-4.0655″

Interference Fit: 0.001 -0.003″

Piston Height: (above) 0.003 -0.010″

Finished Bore Diameter: 3.877 -3.878″

248 Flanged cast liners”

Parent Bore: 4.1045-4.1005″

Recess Depth: 0.150 -0.152″

Outside Diameter: 4,0645-4.0655″

Interference Fit: 0.001 -0.003″

Piston Height: (above) 0.003 -0.010″

Finished Bore Diameter: 3.877 -3.878″

248 Flangless liner Parralell

Parent bore: 4.0615 /4.0625

Outside Diameter: 4.0655-4.0665″

Interference Fit: 0.003 -0.005″

Finished Bore Diameter: 3.9875-3.9795″

If you have more ideas or suggestions to assist send us an email to sales@noordeman.com.au or call 08 9350 6566

We are here to help and keep this knowledge around.