Blog, Technical

NEW ARP 1HDFT 1HDFTE 6LPA HEAD STUD KIT FITTING INSTRUCTIONS

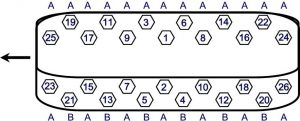

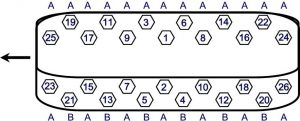

These ARP2000 head studs have been specially designed and manufactured for Toyota 1HD-FT and 1HD-FTE series performance engines. There are twenty (20) x M11 studs at 146 mm long (A), six (6) x M11 studs at 158 mm long (B) and 26 washers and nuts to suit.

The nuts on the six (6) studs beneath the camshaft will interfere with the camshaft lobes if fitted with the supplied washers. These six (6) washers need to be left out or the washer seats on the head spot-faced to a depth of 2mm to give clearance between the nuts and cam lobes.

Put ARP Ultra-Torque lubricant on the thread ends to go into the block and screw in each stud Finger Tight until they bottom out. Do NOT tighten them into the block with a hex key.

Fit the correct thickness head gasket to the block, carefully locating it over the two (2) dowels. Do NOT put any sort of sealant on the head gasket – fit it dry.

Carefully fit the cylinder head over the studs and dowels until it is fully seated.

Fit one of the included washers to each stud, with the bottom face free of lubricant of any type. There should be a thin smear of Ultra-Torque lubricant on the top face of each washer.

Spread a good smear of Ultra-Torque lubricant on the threads of each of the head studs.

Screw down finger tight, one of the included ARP nuts to each stud. The studs may need to be backed off slightly to have a full nut on the stud before tightening.

We have clamp load tested OE bolts using OE tension procedure of 69 N.m (50Ft.lbs) +90° + 90° (Oiled).

This equates to 100 – 110 N.m (74 – 81 Ft.lbs) and an average clamping force of 4989kg (11,000 lbs)

ARP2000 11 mm head studs HSKTO360A have a recommended (3) stage tensioning procedure. For example, 40 N.m (29 Ft.lbs), 80 N.m (59 Ft.lbs) and Final torque.

Final torque of 125 N.m (92 Ft.lbs) will deliver 75% of the fasteners yield strength as clamping load (7,138 kg/15,738 lbs). This is an increase of 40% clamping load over OE head bolts