Blog

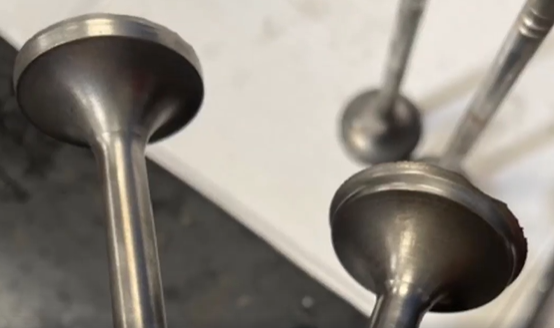

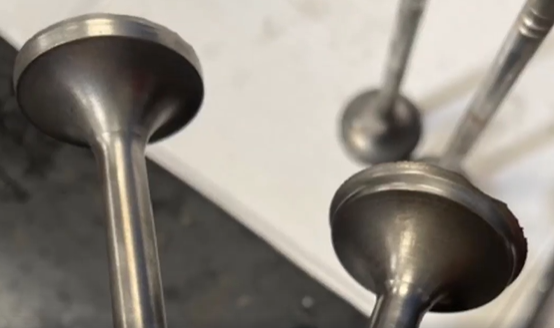

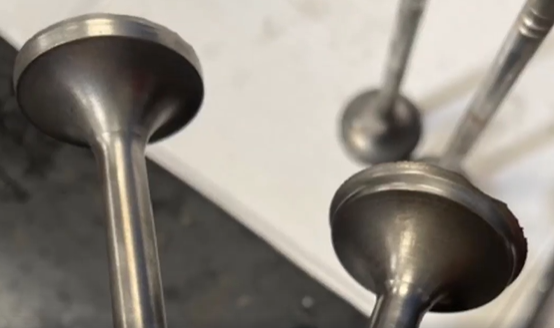

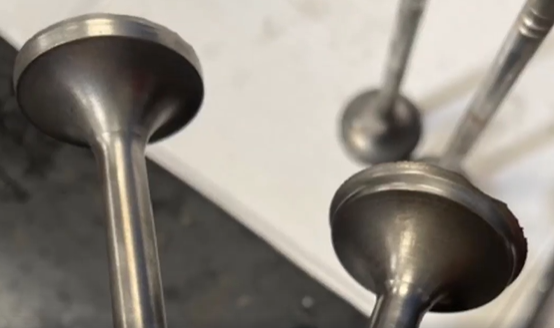

Valve Damage Part 2 Valve face Burning

Valve Failure Analysis |

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

Blog

Valve Failure Analysis |

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

We are here to help you get back on the road again. Make sure you fill in all sections of the form below so that we can get in touch with you about your request.